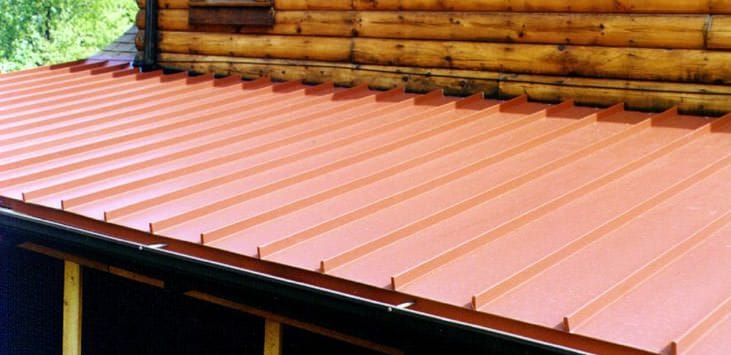

A standing seam in sheet metal materials refers to a specific type of metal panel system where the edges of adjacent panels are vertically raised and interlocked to form a seam. This system is commonly used for roofing and siding applications due to its durability, weather resistance, and clean, modern appearance.

Key Features of Standing Seam

Vertical Seams:

- The panels are joined at raised seams, which typically stand about 1 to 2 inches above the flat surface.

- These seams are either mechanically seamed or snapped together for secure installation.

Hidden Fasteners:

- The fastening system is concealed beneath the seams, preventing exposure to the elements and reducing the risk of leaks or corrosion.

Material Options:

- Commonly made from steel, aluminum, zinc, or copper, offering a variety of finishes and coatings for aesthetic and functional purposes.

Weather Resistance:

- The elevated seams and interlocking design provide excellent water shedding, making it ideal for steep-sloped roofs